The Ultimate Guide to 1-5/8" Feeder Cable for Enhanced Connectivity

Introduction

Picture this: You're standing at the base of a towering cellular network mast, gazing up at the intricate web of cables and antennas that keep our modern world connected. Among these vital components, there's an unsung hero that plays a crucial role in ensuring crystal-clear communication – the 1-5/8" feeder cable. In this comprehensive guide, we're going to dive deep into the world of these remarkable cables, exploring their features, applications, and the game-changing impact they have on our increasingly connected lives.

As a seasoned telecommunications professional with over 15 years of experience, I've seen firsthand how the right choice of feeder cable can make or break a network's performance. The 1-5/8" feeder cable, in particular, has become a go-to solution for many high-capacity systems, and for good reason. Its robust design and impressive capabilities have revolutionized the way we approach signal transmission in various applications.

Throughout this article, we'll unravel the mysteries surrounding 1-5/8" feeder cables, from their basic definition to cutting-edge innovations in the field. Whether you're a curious tech enthusiast, a budding engineer, or a seasoned professional looking to brush up on the latest developments, this guide has something for everyone. So, fasten your seatbelts and get ready for an electrifying journey into the heart of modern connectivity!

Understanding the Importance of Feeder Cables

Before we dive into the specifics of 1-5/8" feeder cables, let's take a moment to appreciate the critical role that feeder cables play in our interconnected world. Imagine them as the arteries of our communication networks, pumping vital signals from transmitters to antennas and vice versa. Without these unassuming yet indispensable components, our phones would fall silent, our internet would grind to a halt, and our modern way of life would be fundamentally altered.

Overview of 1-5/8" Feeder Cable in Telecommunications

Now, let's zoom in on our star player – the 1-5/8" feeder cable. This particular size has gained significant popularity in recent years, and for good reason. Its larger diameter compared to more common sizes like 7/8" or 1/2" allows for higher power handling and lower signal loss over longer distances. This makes it an ideal choice for high-capacity systems and applications where performance is paramount.

In my years of working with various telecommunication systems, I've seen the 1-5/8" feeder cable shine in numerous scenarios. From bustling urban centers with their dense network requirements to remote rural areas where signal strength is crucial, this cable has proven its worth time and time again.

Key Features and Applications

What sets the 1-5/8" feeder cable apart from its smaller counterparts? Let's break it down:

-

Superior Power Handling: Thanks to its larger size, this cable can handle significantly higher power levels without breaking a sweat.

-

Lower Attenuation: Signal loss is the bane of any network engineer's existence. The 1-5/8" cable offers lower attenuation rates, ensuring that signals remain strong over longer distances.

-

Excellent Frequency Range: Whether you're dealing with low-frequency radio signals or high-frequency 5G transmissions, this cable has got you covered.

-

Durability: These cables are built to last, with robust construction that can withstand harsh environmental conditions.

-

Versatility: From broadcast radio to cellular networks, the 1-5/8" feeder cable finds applications across a wide spectrum of communication systems.

As we delve deeper into each of these aspects, you'll gain a newfound appreciation for the engineering marvel that is the 1-5/8" feeder cable. So, let's roll up our sleeves and get into the nitty-gritty!

What is a 1-5/8" Feeder Cable?

Definition and Basic Concepts

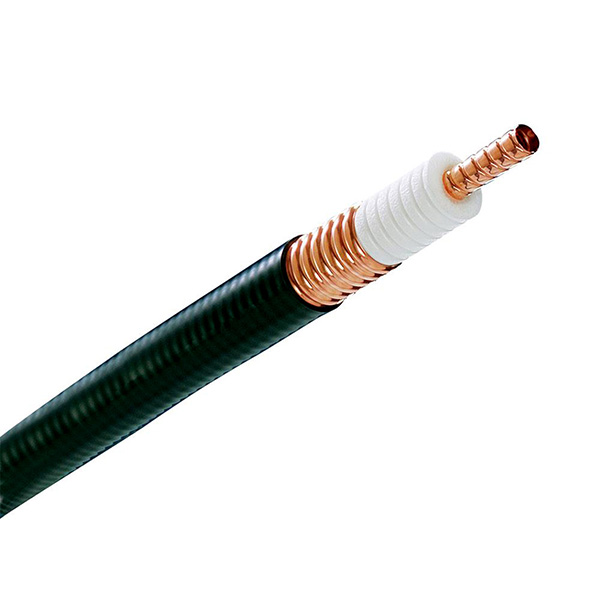

Alright, let's break it down in simple terms. A 1-5/8" feeder cable is a type of coaxial cable used primarily in radio frequency (RF) applications. The "1-5/8" in its name refers to its outer diameter, which is – you guessed it – 1 and 5/8 inches or about 41.3 millimeters. But don't let its size fool you; this cable packs a serious punch when it comes to performance!

In my early days as a field engineer, I remember being amazed at how something seemingly so simple could have such a profound impact on signal quality. The 1-5/8" feeder cable is essentially a conduit for RF energy, designed to transport signals with minimal loss and maximum efficiency.

Physical Characteristics and Dimensions

Let's get up close and personal with the anatomy of a 1-5/8" feeder cable:

-

Outer Conductor: Typically made of corrugated copper or aluminum, this layer provides mechanical strength and acts as an electrical shield.

-

Dielectric: A layer of foam or air-spaced polyethylene that insulates the inner conductor from the outer one.

-

Inner Conductor: Usually a copper tube or wire, this is where the magic happens – it's the primary path for signal transmission.

-

Jacket: An outer protective layer, often made of polyethylene, that shields the cable from environmental factors.

The corrugated design of the outer conductor is a stroke of genius, if you ask me. It not only enhances flexibility but also improves the cable's ability to handle temperature fluctuations without compromising performance. I've seen these cables bend and flex in ways that would make a yoga instructor jealous!

Common Types and Variants

Now, here's where it gets interesting. Not all 1-5/8" feeder cables are created equal. There are several variants, each with its own unique characteristics:

-

Foam Dielectric: These cables use a foam polyethylene dielectric, offering a good balance between performance and flexibility.

-

Air Dielectric: By using air as the primary dielectric material, these cables achieve even lower signal loss, albeit at the cost of being less flexible.

-

Pressurized: Some variants are designed to be pressurized with dry air or nitrogen, providing extra protection against moisture ingress.

-

Fire-Rated: For installations in buildings or tunnels, there are fire-resistant versions that comply with strict safety standards.

In my experience, choosing the right variant can make a world of difference in system performance. I once worked on a project where switching from a standard foam dielectric to an air dielectric cable resulted in a noticeable improvement in signal quality – it was like night and day!

Technical Specifications

Voltage Ratings and Power Handling

Let's talk power – because when it comes to 1-5/8" feeder cables, we're dealing with some serious juice! These cables are typically rated for peak voltages of around 5 kV to 11 kV, depending on the specific model and manufacturer. But what does this mean in practical terms?

Well, imagine you're setting up a high-power radio transmitter. You need a cable that can handle the heat – literally! A 1-5/8" feeder cable can typically handle average power levels of 10 kW or more at frequencies around 100 MHz. That's enough to power a small neighborhood!

I remember a project where we were upgrading a radio station's transmitter. The old 7/8" cable just couldn't cut it with the new high-power equipment. Switching to a 1-5/8" cable not only solved the power handling issues but also improved the overall system efficiency. It was like giving the station a new lease on life!

Impedance and Attenuation Rates

Now, let's dive into some numbers that really matter in the world of RF engineering: impedance and attenuation.

Most 1-5/8" feeder cables have a characteristic impedance of 50 ohms, which is the standard for many RF systems. This impedance matching is crucial for minimizing signal reflections and ensuring maximum power transfer.

As for attenuation, this is where the 1-5/8" cable really shines. At 100 MHz, you're typically looking at attenuation rates of around 0.7 dB per 100 meters. Compare that to a 7/8" cable, which might have attenuation of 1.2 dB per 100 meters at the same frequency, and you can see why the bigger cable is often worth the investment.

Here's a quick comparison I often use to illustrate the point:

- 1-5/8" cable at 100 MHz: ~0.7 dB/100m

- 7/8" cable at 100 MHz: ~1.2 dB/100m

- 1/2" cable at 100 MHz: ~1.9 dB/100m

The difference might seem small, but over long cable runs, it adds up fast!

Frequency Range and Performance

One of the things that impresses me most about 1-5/8" feeder cables is their broad frequency range. These cables can handle frequencies from as low as 1 MHz all the way up to 2.7 GHz or even higher in some cases. This versatility makes them suitable for a wide range of applications, from AM radio to 4G and 5G cellular networks.

But it's not just about the range – it's about maintaining performance across that range. The larger size of the 1-5/8" cable means it can maintain lower attenuation rates even at higher frequencies compared to smaller cables.

For instance, at 2 GHz, you might see attenuation rates of around 4.5 dB per 100 meters for a 1-5/8" cable, compared to 7.5 dB per 100 meters for a 7/8" cable. When you're dealing with high-frequency, high-bandwidth applications like 5G, this difference can be crucial.

I once worked on a 5G installation where we were pushing the limits of what was possible with traditional cabling. The 1-5/8" feeder cable allowed us to achieve the necessary performance without resorting to more complex and expensive solutions. It was a real game-changer!

Applications of 1-5/8" Feeder Cable

Use in Radio Communication Systems

When it comes to radio communication systems, the 1-5/8" feeder cable is often the unsung hero. From AM/FM broadcast stations to shortwave transmitters, these cables play a crucial role in delivering clear, powerful signals.

In broadcast radio, where high power and low loss are paramount, the 1-5/8" cable really comes into its own. I've seen installations where these cables run from transmitters at the base of towers all the way up to antennas hundreds of feet in the air. The low attenuation rates mean that more of the transmitter's power actually makes it to the antenna, resulting in better coverage and clearer signals.

But it's not just about traditional radio. In recent years, I've seen an increasing number of digital radio systems adopting 1-5/8" cables. The cable's ability to handle complex digital signals with minimal distortion makes it ideal for technologies like Digital Audio Broadcasting (DAB) and HD Radio.

Role in Cellular Networks and Towers

If you've ever wondered how your smartphone maintains a strong signal, even in crowded urban areas, you can thank feeder cables like the 1-5/8" variant. These cables are the backbone of many cellular network installations, connecting base station equipment to antennas atop towers and buildings.

The high power handling capacity of 1-5/8" cables makes them particularly useful in macro cell sites, where multiple high-power transmitters might be feeding a single antenna array. I've worked on sites where a single 1-5/8" cable replaced multiple smaller cables, simplifying the installation and improving overall system performance.

With the rollout of 5G networks, the demands on feeder cables have never been higher. The higher frequencies and increased bandwidth of 5G require cables that can deliver low loss and high performance. While some 5G installations are moving towards active antenna systems with integrated electronics, many still rely on traditional passive antennas fed by 1-5/8" cables.

I remember one particularly challenging 5G installation in a dense urban area. We were dealing with limited space and strict performance requirements. The 1-5/8" cable allowed us to achieve the necessary signal strength and quality without having to resort to more complex and expensive solutions.

Industrial and Commercial Use Cases

While telecommunications might be the most visible application for 1-5/8" feeder cables, they're also widely used in various industrial and commercial settings. Here are a few examples I've encountered in my career:

-

Broadcast Television: Similar to radio broadcasting, TV stations often use 1-5/8" cables to connect transmitters to antennas, especially for high-power UHF stations.

-

Radar Systems: In applications like weather radar or air traffic control, where high power and low loss are critical, 1-5/8" cables are often the go-to choice.

-

Scientific Research: I once worked on a project for a radio telescope array where 1-5/8" cables were used to carry the incredibly weak signals from the antennas to the processing equipment with minimal loss.

-

Industrial RF Heating: In processes like plastic welding or wood drying that use RF energy, 1-5/8" cables are often used to deliver high power from the RF generator to the applicator.

-

Emergency Communication Systems: For critical infrastructure like emergency response networks, the reliability and performance of 1-5/8" cables make them a popular choice.

One particularly memorable project involved a large-scale distributed antenna system (DAS) for a major sports stadium. We used 1-5/8" feeder cables as the main distribution lines, branching off to smaller cables for individual antennas. The result was a system that could handle the massive data demands of tens of thousands of smartphone-wielding fans without breaking a sweat.

The versatility of 1-5/8" feeder cables never ceases to amaze me. From the top of cellular towers to the depths of research facilities, these cables are quietly keeping our modern world connected and running smoothly.

Advantages of Using 1-5/8" Feeder Cable

Enhanced Signal Transmission Efficiency

When it comes to signal transmission, efficiency is the name of the game, and this is where 1-5/8" feeder cables truly shine. The larger diameter of these cables translates to lower signal loss, which means more of the transmitted power actually reaches its destination.

Let me paint a picture for you: Imagine you're trying to water a garden with a hose. A thin hose (like a smaller cable) might result in a weak trickle at the end, especially over long distances. But a wider hose (our 1-5/8" cable) allows for a strong, consistent flow even over greater lengths. That's essentially what we're achieving with signal transmission in these larger cables.

I once worked on a project upgrading a rural radio station's transmission system. By switching from a 7/8" cable to a 1-5/8" cable, we were able to extend the station's effective range by almost 20% without increasing transmitter power. The improvement in signal quality was so noticeable that listeners called in to compliment the station on its "new sound"!

Durability and Weather Resistance

In my years in the field, I've seen cables subjected to everything from scorching desert heat to arctic blizzards, and let me tell you, 1-5/8" feeder cables are tough cookies. Their robust construction makes them highly resistant to physical damage, while their weather-resistant properties ensure they can withstand harsh environmental conditions.

The outer jacket of these cables is typically made from high-density polyethylene (HDPE) or a similar material, which provides excellent protection against UV radiation, moisture, and temperature extremes. The corrugated design of the outer conductor not only enhances flexibility but also improves the cable's ability to withstand thermal expansion and contraction without compromising performance.

I remember a particularly challenging installation on a mountaintop communications tower. The site was exposed to high winds, frequent lightning strikes, and severe temperature fluctuations. We chose a 1-5/8" cable with enhanced weather resistance, and five years later, it's still performing flawlessly despite the harsh conditions.

Cost-Effectiveness and Longevity

Now, I know what you might be thinking – "Bigger cable, bigger price tag, right?" Well, not necessarily when you look at the big picture. While it's true that 1-5/8" feeder cables have a higher upfront cost compared to smaller alternatives, they often prove more cost-effective in the long run.

Here's why:

-

Lower Loss = Higher Efficiency: The reduced signal loss means you might be able to use a lower power transmitter, saving on energy costs over time.

-

Fewer Replacements: The durability of these cables means they need to be replaced less frequently, reducing maintenance costs and downtime.

-

Future-Proofing: The high capacity of 1-5/8" cables means they can often accommodate system upgrades without needing to be replaced.

-

Simplified Installations: In some cases, a single 1-5/8" cable can replace multiple smaller cables, simplifying installation and reducing overall material costs.

I once consulted on a project where a company was debating between using multiple 7/8" cables or a single 1-5/8" cable for a new cellular installation. We ran the numbers, factoring in installation costs, expected lifespan, and potential future upgrades. The 1-5/8" option ended up being about 15% cheaper over a 10-year period, not to mention the performance benefits.

The longevity of these cables is truly impressive. I've seen 1-5/8" feeder cables in service for 20+ years, still performing within spec. Of course, this depends on factors like installation quality and environmental conditions, but with proper installation and maintenance, these cables can be a long-term investment in your system's performance and reliability.

Installation Guidelines

Preparing for Installation

Proper preparation is key to a successful 1-5/8" feeder cable installation. Here's a checklist I always run through before starting any installation:

-

Site Survey: Conduct a thorough site survey to determine the best cable route, identifying potential obstacles and hazards.

-

Tools and Equipment: Ensure you have all necessary tools, including cable cutters, hoisting grips, weatherproofing kits, and appropriate connectors.

-

Safety Gear: Don't forget personal protective equipment (PPE) such as hard hats, safety glasses, and fall protection gear for tower work.

-

Cable Specifications: Review the cable's specifications, including minimum bend radius and maximum pulling tension.

-

Grounding Plan: Develop a comprehensive grounding plan to protect against lightning and static buildup.

-

Weather Check: Plan the installation for a day with favorable weather conditions, especially for outdoor or tower installations.

I once had a colleague who skipped the site survey on a "simple" installation. Halfway through, we discovered an unexpected conduit blockage that forced us to reroute the entire cable run. A proper survey would have saved us hours of work and a lot of headaches!

Step-by-Step Installation Process

Now, let's walk through the installation process:

-

Unspooling: Carefully unspool the cable, avoiding kinks or twists. For long runs, use a cable reel stand to ensure smooth feeding.

-

Routing: Guide the cable along the planned route, using cable trays or conduits where appropriate. Remember to leave some slack for connections and future adjustments.

-

Bending: When making turns, respect the minimum bend radius (typically about 10 inches for 1-5/8" cable). Sharp bends can damage the cable and degrade performance.

-

Supporting: Use proper hangers or clamps designed for 1-5/8" cable. Space them appropriately to support the cable's weight without causing deformation.

-

Connector Installation: Carefully prepare the cable ends and attach the appropriate connectors. This is a critical step that requires precision – a poorly installed connector can negate all the benefits of using a high-quality cable.

-

Weatherproofing: Apply weatherproofing materials to all outdoor connections to prevent moisture ingress.

-

Grounding: Install grounding kits at regular intervals and at both ends of the cable run.

-

Testing: Conduct thorough testing, including continuity checks and return loss measurements, to ensure the installation meets specifications.

I remember an installation where we had to run a 1-5/8" cable up a 200-foot tower. We used a combination of hoisting grips and a pulley system to carefully raise the cable, with team members at various levels guiding it to prevent damage. It was like a well-choreographed dance – challenging, but incredibly satisfying when completed successfully.

Best Practices for Optimum Performance

To ensure your 1-5/8" feeder cable installation performs at its best, keep these best practices in mind:

-

Minimize Connections: Each connection point introduces potential signal loss. Try to use continuous cable runs where possible.

-

Proper Alignment: Ensure connectors are perfectly aligned and fully tightened to maintain the cable's impedance characteristics.

-

Avoid Stress Points: Use appropriate strain relief at connection points and support the cable properly to avoid stress that could lead to damage over time.

-

Regular Inspections: Implement a routine inspection schedule to catch and address any issues early.

-

Documentation: Keep detailed records of the installation, including cable routes, connector types, and any special considerations for future reference.

-

Temperature Considerations: In areas with extreme temperature variations, allow for cable expansion and contraction in your installation design.

-

Moisture Prevention: Use "drip loops" where cables enter buildings or enclosures to prevent water from following the cable inside.

One of the most important lessons I've learned is the value of taking your time and doing the job right. I once saw a rushed installation where corners were cut to meet a deadline. Within six months, they were experiencing signal issues and had to redo the entire installation. The old adage "measure twice, cut once" definitely applies to cable installation!

Remember, a well-installed 1-5/8" feeder cable can provide decades of reliable service. It's worth investing the time and effort to ensure it's done correctly from the start.

Maintenance and Troubleshooting

Routine Maintenance Tips

Maintaining 1-5/8" feeder cables is crucial for ensuring long-term performance and reliability. Here are some key maintenance tips I've gathered over the years:

-

Regular Visual Inspections: Conduct visual checks at least annually, looking for signs of physical damage, corrosion, or loose connections.

-

Weatherproofing Checks: Inspect and replace weatherproofing materials as needed, especially after severe weather events.

-

Connector Tightness: Periodically check and retighten connectors, as they can loosen over time due to thermal cycling and vibration.

-

Grounding System Verification: Ensure all grounding connections are intact and corrosion-free.

-

Cable Support Inspection: Check cable hangers and supports for signs of wear or damage.

-

Electrical Testing: Perform annual sweep tests to verify the cable's electrical performance hasn't degraded.

-

Pressurization Checks: For pressurized systems, regularly monitor and maintain proper pressure levels.

I once worked on a site where routine maintenance had been neglected for years. When we finally got around to it, we found several issues that could have led to major failures if left unchecked. A little preventive maintenance goes a long way in avoiding costly downtime and repairs.

Identifying and Solving Common Issues

Even with the best maintenance, issues can still arise. Here are some common problems I've encountered with 1-5/8" feeder cables and how to address them:

-

High VSWR (Voltage Standing Wave Ratio):

- Possible causes: Loose or corroded connectors, water ingress, cable damage

- Solution: Check and replace connectors, inspect cable for damage, ensure proper weatherproofing

- Signal Loss:

- Possible causes: Cable degradation, loose connections, excessive bending

- Solution: Perform sweep tests, check connector tightness, verify cable routing

- Intermittent Performance:

- Possible causes: Loose connections, partial breaks in the cable

- Solution: Wiggle test connections, perform TDR (Time Domain Reflectometry) testing

- Physical Damage:

- Possible causes: Environmental factors, accidental impacts

- Solution: Replace damaged sections, improve physical protection if necessary

- Moisture Ingress:

- Possible causes: Damaged jacket, poor weatherproofing

- Solution: Locate and seal entry points, improve drainage, replace affected sections if necessary

I remember a particularly tricky case where a station was experiencing intermittent signal drops. After exhaustive testing, we discovered that a tree branch was occasionally brushing against the cable during high winds, causing momentary disruptions. The solution was as simple as trimming the tree, but it took some real detective work to identify the problem!

Ensuring Safety During Operation

Safety should always be the top priority when working with 1-5/8" feeder cables, especially in high-power systems. Here are some crucial safety tips:

-

RF Exposure: Always follow RF safety guidelines and use appropriate personal RF monitors when working near active antennas.

-

Power Down: Whenever possible, power down the system before performing maintenance on the cable.

-

Lockout/Tagout: Implement proper lockout/tagout procedures to prevent accidental power-up during maintenance.

-

Grounding: Ensure proper grounding before touching any part of the cable system to dissipate any stored charge.

-

Fall Protection: When working at heights, always use appropriate fall protection equipment.

-

Team Communication: Maintain clear communication with all team members during maintenance operations.

-

Weather Awareness: Be mindful of weather conditions, especially when working on towers or exposed areas.

I once witnessed a near-miss incident where a technician almost contacted a live 1-5/8" cable carrying several kilowatts of RF power. It was a stark reminder of the importance of safety protocols and situational awareness when working with these high-power systems.

Remember, no maintenance task is so urgent that it can't be done safely. Always take the time to assess risks and implement proper safety measures before starting any work on 1-5/8" feeder cable systems.

Comparison with Other Feeder Cable Sizes

Differences Between 1-5/8" and Other Common Sizes (e.g., 7/8", 1-1/2")

In the world of RF feeder cables, size really does matter. Let's compare the 1-5/8" cable with some other common sizes:

-

7/8" Cable:

- Smaller and more flexible than 1-5/8"

- Higher attenuation (more signal loss)

- Lower power handling capacity

- Often used in smaller cell sites or as jumper cables

- 1-1/2" Cable:

- Slightly smaller than 1-5/8"

- Performance characteristics fall between 7/8" and 1-5/8"

- Good balance of power handling and flexibility

- 2" Cable:

- Larger than 1-5/8"

- Even lower attenuation and higher power handling

- Less flexible and more challenging to install

I remember a project where we were upgrading a network from 7/8" to 1-5/8" cables. The improvement in signal strength and quality was immediately noticeable. It was like upgrading from a garden hose to a fire hose!

Pros and Cons of Each Size

Let's break down the advantages and disadvantages of each size:

-

7/8" Cable:

Pros:- More flexible and easier to install

- Lower cost

- Suitable for shorter runs and lower power systems

Cons: - Higher signal loss, especially at higher frequencies

- Lower power handling capacity

- 1-1/2" Cable:

Pros:- Good balance of performance and manageability

- Lower loss than 7/8" but more flexible than 1-5/8"

Cons: - Not as widely used, potentially limiting connector and accessory options

- 1-5/8" Cable:

Pros:- Excellent power handling capacity

- Low signal loss, even over long distances

- Widely used, with good availability of accessories

Cons: - Less flexible than smaller cables

- Higher initial cost

- 2" Cable:

Pros:- Lowest signal loss

- Highest power handling capacity

Cons: - Least flexible, challenging to install

- Highest cost

- May be overkill for many applications

In my experience, the choice often comes down to finding the right balance between performance requirements and practical installation considerations.

When to Choose 1-5/8" Over Other Options

Choosing the right cable size is crucial for system performance and cost-effectiveness. Here are scenarios where 1-5/8" cable is often the best choice:

-

High Power Transmission: For systems running at high power levels (typically above 4-5 kW), 1-5/8" cable provides the necessary power handling capacity.

-

Long Cable Runs: When dealing with long distances between the transmitter and antenna, the lower attenuation of 1-5/8" cable becomes significant.

-

High Frequency Applications: As you move into higher frequencies (like those used in 5G), the performance advantage of 1-5/8" cable becomes more pronounced.

-

Future-Proofing: If you anticipate future upgrades to higher power or frequency, starting with 1-5/8" cable can save on future replacement costs.

-

Multiple Channel Systems: In broadcast applications where multiple channels are combined into a single antenna, the power handling of 1-5/8" cable is often necessary.

I once consulted on a project for a mountain-top broadcast site. Initially, they were considering 7/8" cable to save on installation costs. However, after analyzing the long-term plans for the site, including potential power increases and additional services, we opted for 1-5/8" cable. Five years later, they were able to add new channels without any cable upgrades, validating the decision.

Remember, while 1-5/8" cable offers superior performance in many scenarios, it's not always the best choice. For smaller cell sites, indoor DAS systems, or applications where flexibility is crucial, smaller cable sizes might be more appropriate. Always consider the specific requirements of your project, including power levels, frequencies, distance, installation constraints, and future expansion plans when selecting cable size.

Future Trends and Innovations

Emerging Technologies in Feeder Cables

The world of RF technology is constantly evolving, and feeder cables are no exception. Here are some exciting trends and innovations I've been keeping an eye on:

-

Advanced Dielectric Materials: Researchers are developing new dielectric materials that promise even lower signal loss and higher power handling capabilities. Some of these materials incorporate nanotechnology to achieve previously impossible performance levels.

-

Composite Conductors: New composite materials for inner and outer conductors are being explored, aiming to reduce weight while maintaining or even improving electrical performance.

-

Smart Cables: Integration of fiber optics or other sensors within the cable structure to allow real-time monitoring of performance and early detection of potential issues.

-

Enhanced Weatherproofing: Development of new jacket materials and designs that offer superior protection against environmental factors, potentially extending cable lifespan in harsh conditions.

-

Improved Flexibility: Innovations in cable design are focusing on increasing flexibility without compromising performance, making installation easier, especially in tight spaces.

I recently attended a conference where a prototype "self-healing" cable was presented. It incorporated a special polymer that could automatically seal small punctures or cuts in the outer jacket. While still in the early stages, it's innovations like these that could revolutionize the industry.

Integration with Modern Telecommunication Infrastructure

As telecommunications infrastructure continues to evolve, so does the role of feeder cables like the 1-5/8" variant. Here are some ways these cables are being integrated into modern systems:

-

5G and Beyond: While some 5G installations use active antenna systems with integrated electronics, many still rely on traditional passive antennas fed by high-performance cables like 1-5/8" feeders. As we move towards 6G and beyond, the demand for high-capacity, low-loss transmission lines will only increase.

-

Massive MIMO Systems: These advanced antenna systems, crucial for 5G, often require multiple high-capacity feeder lines. 1-5/8" cables are well-suited for this application due to their low loss and high power handling.

-

Edge Computing: As data processing moves closer to the network edge, there's an increasing need for robust, high-capacity connections between edge computing facilities and antenna systems. 1-5/8" feeder cables play a crucial role in these setups.

-

IoT and Smart Cities: The proliferation of IoT devices and smart city initiatives is driving the need for more robust and efficient communication infrastructure, where high-performance feeder cables are essential.

-

Hybrid Fiber-Coax Networks: In some applications, 1-5/8" coaxial feeders are being used in conjunction with fiber optic cables to create hybrid systems that leverage the strengths of both technologies.

I recently worked on a smart city project where we used 1-5/8" feeder cables to connect a network of high-capacity, multi-band antennas. The system supported everything from municipal Wi-Fi to traffic management systems, showcasing the versatility of these cables in modern, integrated infrastructures.

Mobile Signal Booster

Mobile Signal Booster